|

ArNi® wire was

designed by Shunyata Research to be

the finest quality wire available.

It begins with the highest purity of

copper and silver metals available,

including Ohno (single crystal),

PCOCC silver and OFE C0101

conductors. Fluorocarbon dielectrics,

usually only found in aerospace

applications that have exceptional

electrical characteristics including

extremely low dielectric absorption,

high dielectric strength and superb

heat resistance. When used in

digital wiring it significantly

reduces transient energy storage and

release which affects phase noise

performance. And finally every cable

undergoes our proprietary KPIP™

process.

VTX-Ag

cables are uniquely

constructed with both an

inner, center conductor made

of pure silver and an outer

concentric ring conductor

made of pure copper. It is

made using the finest

fluorocarbon insulation to

minimize dielectric

absorption and re-radiation

which translates to an

improvement in resolution

and clarity. VTX-Ag delivers

the speed and clarity of

silver and the midrange

warmth and three dimensional

power in the lower octaves

of copper without imparting

any of the negatives

associated with either metal.

The best qualities of silver

and copper combined. VTX-Ag

cables are uniquely

constructed with both an

inner, center conductor made

of pure silver and an outer

concentric ring conductor

made of pure copper. It is

made using the finest

fluorocarbon insulation to

minimize dielectric

absorption and re-radiation

which translates to an

improvement in resolution

and clarity. VTX-Ag delivers

the speed and clarity of

silver and the midrange

warmth and three dimensional

power in the lower octaves

of copper without imparting

any of the negatives

associated with either metal.

The best qualities of silver

and copper combined.

Shunyata

Research uses only the

highest purity of copper

available for the production

of its wire products. OFE

Alloy 101 or C10100 is

the highest grade of copper

with a minimum 99.99% purity

and a conductivity rating of

101% IACS. OFE stands for

oxygen-free electrolytic and

supersedes the term OFHC (oxygen-free

high conductivity). C10100

is the only grade of copper

that comes with a written

certification of purity.

Certified by ASTM F68 C10100 Shunyata

Research uses only the

highest purity of copper

available for the production

of its wire products. OFE

Alloy 101 or C10100 is

the highest grade of copper

with a minimum 99.99% purity

and a conductivity rating of

101% IACS. OFE stands for

oxygen-free electrolytic and

supersedes the term OFHC (oxygen-free

high conductivity). C10100

is the only grade of copper

that comes with a written

certification of purity.

Certified by ASTM F68 C10100

Simple

crimping, soldering, brazing

and screws are all inferior

methods of joining two wires

or terminals together.

Sonic welding uses

high-energy sonic waves to

literally join two metals

together at a molecular

level and cold-welding uses

high-energy pneumatic

pressure to bond metals.

Shunyata Research uses both

methods to secure

connections that do not

degrade over time. Superior

contact and wire connections.

Kinetic Phase Inversion

Processing was developed by

Caelin Gabriel after years of

research into the underlying causes

of various effects such as burn-in,

wire directionality and the effects

of cryogenic treatment. He

discovered that there was an

underlying core principle that

burn-in and cryogenics only

partially addressed. Once the

governing principle was understood

it became possible to create a

processor that reduces the need for

long burn-in periods and eliminates

the effects of cryogenic treatment.

Four-days of continuous KPIP™

processing dramatically reduces the

sonic ups and downs associated with

burn-in, delivering a relaxed and

natural presentation.

Specifications

- Cable Type: VTX-Ag 08

- Conductors: ArNi ® OFE

- Dielectric: fluorocarbon

- Connectors: STIS V3 connectors

- HARP Module: NA

- KPIP Processing: 4-days

- Standard Length: 2.00 meters

- Safety Assurance: Continuity and

polarity tests – by two technicians

HiPOT tests insulation breakdown @ 1,200 VAC

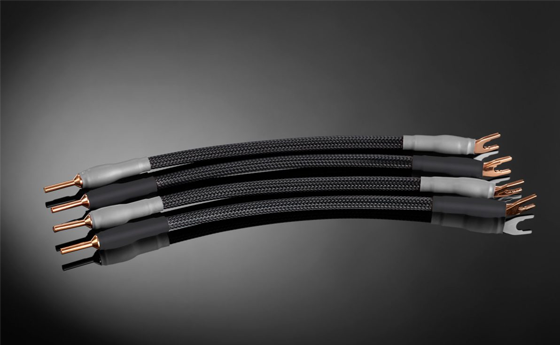

DELTA v2 Speaker Jumper

- Cable Type: VTX 08

- Conductors: ArNi ® OFE

- Dielectric: fluorocarbon

- Connectors: STIS V3 connectors

- HARP Module: NA

- KPIP Processing: 4-days

- Standard Length: .25 meters

- Safety Assurance: Continuity and

polarity tests – by two technicians

HiPOT tests insulation breakdown @ 1,200 VAC

Voor de beschikbare lengtes van

deze kabel raadpleeg de

prijslijst. |