|

RAISING THE BAR

Theta Series signal, digital, and

power cables were created using

scientific innovation that has

established Shunyata Research as a

key contributor to the world's top

recording studios and heart-surgery

labs. Each component, material, and

conductor within the Theta Series is

custom-designed to extend the

boundaries of signal resolution,

even when compared to cost-no-object

products. Theta Series products

further expand upon Shunyata

Research's legacy of delivering

uncompromising performance at prices

that raise expectations for all

products in their category.

ADVANCING TECHNOLOGY

Theta Series signal and digital

cable products feature

continuous-cast Ohno copper. Ohno

copper is an ultra-pure conductor

drawn using heated molds that cast

the wire into a singular crystalline

structure. The Ohno conductors used

in the Theta Series are then

extruded with a fluorocarbon

dielectric and custom-shielding

elements using Shunyata Research's

exclusive PMZ (Precision Matched

Impedance) process. This extrusion

method tightens the tolerances of

the conductor surface, dielectric

and the precision placement of the

shield. To achieve these finely

drawn tolerances, the extrusion and

braiding machines must be run at

one-quarter normal speed during the

manufacturing process. Theta speaker

cables and power cords feature VTX™

(hollow core) and VTX-Ag™ (pure

silver center) conductors, both with

an outer layer of ultra-pure OFE

copper for enhanced performance.

Finally, all Theta cables are

conditioned for 4-days using

Shunyata Research's advanced Kinetic

Phase Inversion ProcessTM

(KPIPv2TM), which conditions

conductor metals at a molecular

level. Theta Series cables are

terminated with Shunyata's

custom-designed connectors and

cold-soldered terminals. These

custom-designed attributes elevate

Theta Series performance far beyond

expectation, regardless of cost.

THE SOUND AND FURY

Theta cables disappear, allowing the

system to express sudden dynamic

shifts in timing and frequency

extension with effortlessness and

nuance. A loom of Theta cables

allows a complex system of

electronics and speakers to speak

with a single coherent voice. Like

their more affordable Gamma Series

counterpart, Theta cables imbue the

system with an unassailable sense of

coherence, as if everything is in

focus, without distortion or hard

transients. There is an absence of

perceived noise, allowing spectral

and textural subtlety to come to the

fore. Unlike common copper cables,

Theta Series cables deliver

explosive dynamics and pitch perfect

frequency extension, even when

compared to far more expensive

cables. Theta's larger gauge VTX™

conductors add weight,

dimensionality and an expansive,

room-filling sound-stage.

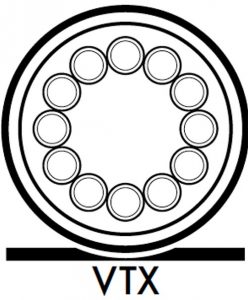

TECHNOLOGY

Shunyata’s

VTX-Ag cables are uniquely

constructed with both an inner,

center conductor made of pure silver

and an outer concentric ring

conductor made of pure copper. It’s

made using the finest fluorocarbon

insulation to minimize dielectric

absorption and re-radiation which

translates to an improvement in

resolution and clarity. VTX-Ag

delivers the speed and clarity of

silver and the midrange warmth and

three dimensional power in the lower

octaves of copper without imparting

any of the negatives associated with

either metal. – The best qualities

of silver and copper combined Shunyata’s

VTX-Ag cables are uniquely

constructed with both an inner,

center conductor made of pure silver

and an outer concentric ring

conductor made of pure copper. It’s

made using the finest fluorocarbon

insulation to minimize dielectric

absorption and re-radiation which

translates to an improvement in

resolution and clarity. VTX-Ag

delivers the speed and clarity of

silver and the midrange warmth and

three dimensional power in the lower

octaves of copper without imparting

any of the negatives associated with

either metal. – The best qualities

of silver and copper combined

ArNi® is a type of wire created by

Shunyata Research designed to be the

finest quality wire available for

audio purposes. It begins with the

highest purity of copper available –

OFE C10100 or Ohno (single crystal).

Then it is formed in virtual hollow

tubes eliminating skin effects and

eddy current distortions. A premium

fluorocarbon insulation minimizes

dielectric absorption and

re-radiation, greatly improving

resolution and clarity. In addition,

the wire undergoes our proprietary

KPIP™ process.

Shunyata

Research uses only the highest

purity of copper available for the

production of its wire products.

OFE Alloy 101 or C10100 is the

highest grade of copper with a

minimum 99.99% purity and a

conductivity rating of 101% IACS.

OFE stands for oxygen-free

electrolytic and supersedes the term

OFHC (oxygen-free high conductivity).

C10100 is the only grade of copper

that comes with a written

certification of purity. Certified

by ASTM F68 C10100. Shunyata

Research uses only the highest

purity of copper available for the

production of its wire products.

OFE Alloy 101 or C10100 is the

highest grade of copper with a

minimum 99.99% purity and a

conductivity rating of 101% IACS.

OFE stands for oxygen-free

electrolytic and supersedes the term

OFHC (oxygen-free high conductivity).

C10100 is the only grade of copper

that comes with a written

certification of purity. Certified

by ASTM F68 C10100.

Fluorocarbon

dielectrics are usually only found

in wire used in the aerospace

industry, satellites and only the

most expensive audiophile cabling.

It has special electrical

characteristics; very low dielectric

absorption, high dielectric strength

and exceptional heat resistance.

When used in audio and power cables

is reduces the perception of dynamic

compression and it improves sonic

low-level resolution and clarity.

Crystal clear transient detail. Fluorocarbon

dielectrics are usually only found

in wire used in the aerospace

industry, satellites and only the

most expensive audiophile cabling.

It has special electrical

characteristics; very low dielectric

absorption, high dielectric strength

and exceptional heat resistance.

When used in audio and power cables

is reduces the perception of dynamic

compression and it improves sonic

low-level resolution and clarity.

Crystal clear transient detail.

Audiophile Grade Connectors

Shunyata’s audiophile-grade AC

connectors are specially crafted

from high-grade solid brass to

accommodate large 10-gauge

conductors and feature gold-plated

pure copper contacts in the IEC

connectors. This combination results

in lower resistance and ensures a

lifetime of exceptional sound.

Hermetically Sealed

Within robust polycarbonate

head-shells, the connectors are

hermetically sealed with an

electrically inert compound that

protects the contacts and wires from

corrosion. The compound also ensures

that the wires cannot become loose,

fray, or pull out from the

head-shell. This guarantees reliable

performance that does not degrade

over time.

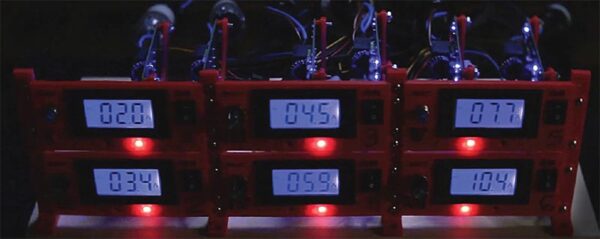

KPIP Blackbird Processor

|

|

Shunyata Research’s

proprietary Kinetic

Phase Inversion Process

includes four days of

continuous KPIP v2™

processing which refines

conductor metals at a

molecular level. This

dramatically reduces

burn-in time and

significantly improves

sonic performance,

delivering a relaxed and

life-like presentation.

When compared to the

original process, KPIP

v2™ represents a

dramatic performance

upgrade on par with a

component-level upgrade. |

SPECIFICATIONS

- Conductors: OFE & Silver

- Gauge: 10

- Tech: VTX-Ag™

- Construction: Extruded cable

- Dielectric: Fluorocarbon

- Noise Reduction: > 12 dB @ 1 MHz

- AC Connector: Audiophile grade,

solid brass contacts

- IEC Connector: Audiophile grade,

gold plated pure copper contacts

- KPIP v2 Processing: 4-days

- Color: Black flex

- Standard Length: 1.75 meters

Safety Assurance:

- Continuity and polarity tests – by

two technicians

- HiPOT tests insulation breakdown @

4,500 VAC |