|

THEY SIMPLY LET THE

MUSIC FLOW

Occasionally, products come along

that represent a paradigm shift

within a given category. Using 25

years worth of Shunyata Research's

documented science, experience and

innovation, Gamma Series cables are

poised to upend price and

performance axioms within the cable

industry. Shunyata Research has made

critical advancements in conductor

science and applied them to Gamma

Series cables, elevating performance

far beyond expectation. Perhaps more

than any other product in Shunyata

Research's history, Gamma Series

cables demand to be heard even when

compared to cables two to three

times the cost.

DRIVEN BY SCIENCE

Gamma signal and digital cables are

made with the finest conductors

available. Single-crystal,

continuous cast Ohno copper is an

ultra-pure conductor normally found

in far more expensive cables. Ohno

conductors are extruded using

Shunyata Research's exclusive PMZ (Precision

Matched Impedance) process. This

extrusion method tightens the

tolerances of the conductor

surfaces, dielectric extrusions, and

the precision of the braided shield.

All are held to minute tolerances.

The extrusion and braiding machines

must be run at one-quarter speed

during the manufacturing process.

Finally, all Gamma cables are

conditioned for 4 days using

advanced Kinetic Phase Inversion

Process (KPIP v2™).

PURITY IN TONE.

DYNAMIC BY NATURE.

If choosing a single word to

encapsulate the sound of a Gamma

Series cable system, it would be

coherence. Every aspect of Gamma

cable system performance simply

flows with the ease and clarity of a

single voice. Textural and tonal

nuance is balanced perfectly against

Gamma's explosive, dynamic nature.

Gamma cable systems never sound

forward, bright, aggressive or edgy.

However, what truly separates Gamma

cables from all others, regardless

of cost, is their self-effacing

alacrity, timing accuracy, dynamic

punch and frequency extension. Most

pure-copper cables, even expensive

models, may sound warm, rich, and

full bodied at the expense of

accurate timing, dynamics and

frequency extension. Gamma cables

sound very natural, but are

surprisingly agile, athletic and

entirely unforced with regard to

expressing frequency extension,

timing, weight and authority in the

low octaves. Gamma cables do all of

this without calling attention to

themselves, allowing the purity of

the sound to take center stage.

TECHNOLOGY

|

|

Ohno

wire, also called PCOCC was

invented in 1986 by

professor Atsumi Ohno of

the Chiba Institute of

Technology in Japan. Copper

wire is created by an

extrusion process that pulls

a rod of cold copper through

a small orifice which

creates multiple crystalline

boundaries. By contrast,

Ohno wire is made by a

process using heated molds

that cast a wire to form a

single crystalline structure.

Ohno wire is well known

for its exceptionally pure,

grain-free sonic qualities. |

| |

|

|

|

|

Fluorocarbon dielectrics are

usually only found in wire

used in the aerospace

industry, satellites and

only the most expensive

audiophile cabling. It has

special electrical

characteristics; very low

dielectric absorption, high

dielectric strength and

exceptional heat resistance.

When used in audio and power

cables is reduces the

perception of dynamic

compression and it improves

sonic low-level resolution

and clarity.

Crystal clear

transient detail. |

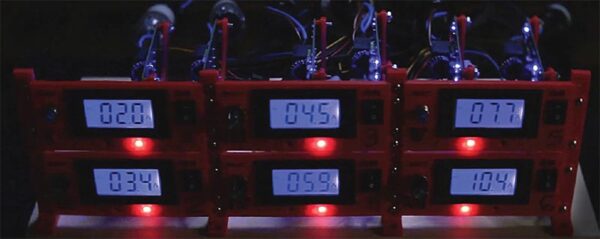

KPIP v2™ PROCESSING

|

|

Shunyata

Research’s proprietary

Kinetic Phase Inversion

Process includes four days

of continuous KPIP v2™

processing which refines

conductor metals at a

molecular level. This

dramatically reduces burn-in

time and significantly

improves sonic performance,

delivering a relaxed and

life-like presentation. When

compared to the original

process, KPIP v2™ represents

a dramatic performance

upgrade on par with a

component-level upgrade. |

SPECIFICATIONS

- Cable Type: Twin axial geometry

- Conductors: OCC (Ohno Continuous

Cast) copper (tinned)

- Shield: 100% coverage foil shield

- Dielectric: Fluorocarbon

- Connectors: Gold plated brass

contacts, nickel matte finish

- Gauge: 18

- Color: Charcoal Flex

- KPIP v2 Processing: 4-days

- Standard Length: 1.00 meters

Safety Assurance:

- Continuity and polarity tests – by

two technicians

- HiPOT tests insulation breakdown @

1,200 VAC |